Trolleys for DC chain hoists

Smooth travel, low travel resistance

Trolleys for DC chain hoists

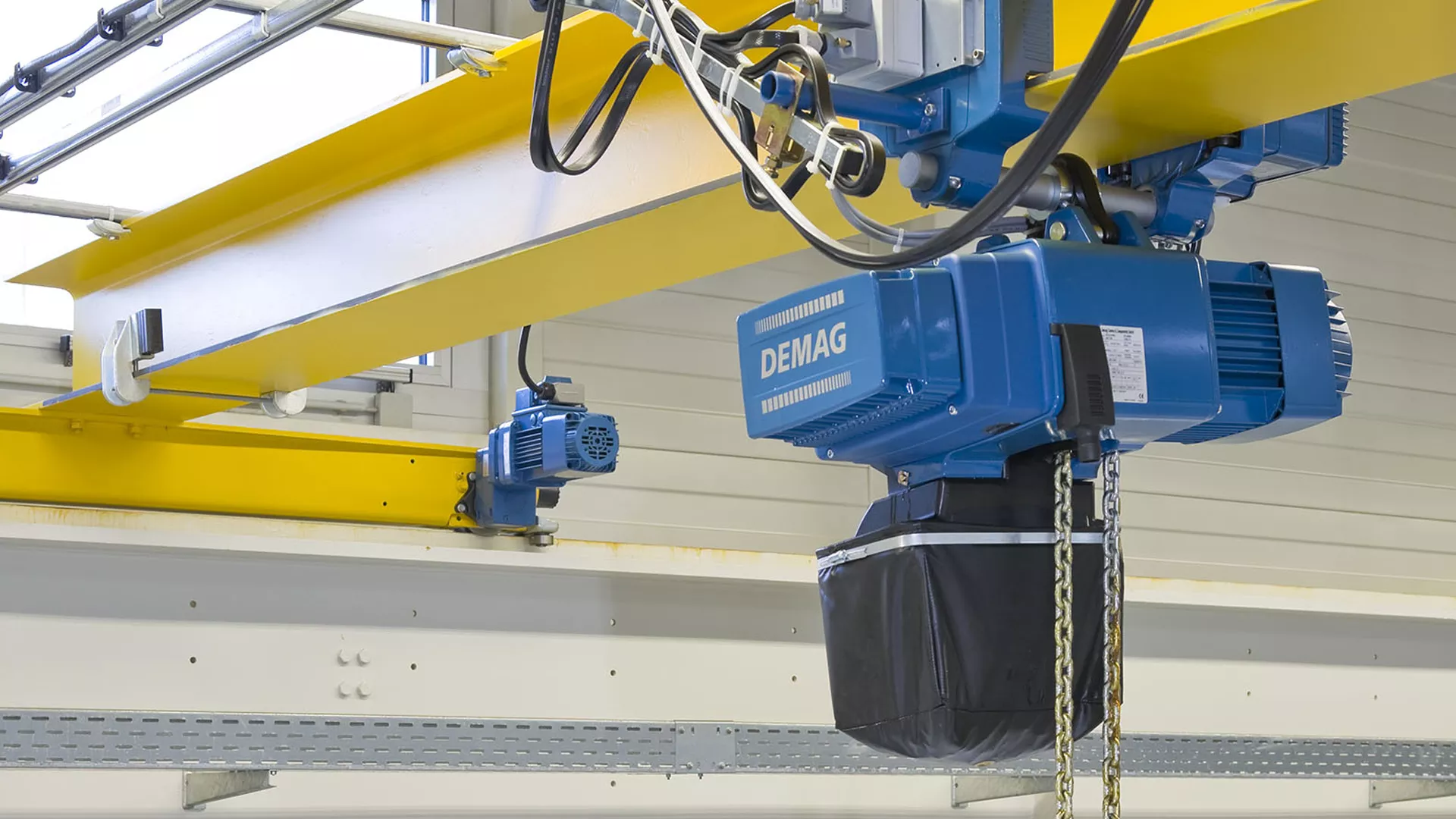

Demag trolleys for chain hoists are a perfect match for DC chain hoists and ideal for installation on I-beam girders or on the modular KBK light crane system. For push travel or with electric positioning – these trolleys provide horizontal travel solutions tailored to meet specific requirements for our compact hoist units.

All trolleys feature a low rolling resistance and smooth travel characteristics over their entire service life. The robust components are perfectly matched and can provide convenient transport solutions for your application needs.

Demag trolleys – the choice is yours:

- U type trolleys for manual travel

- E type trolleys for low-sway electric travel

- Click-fit trolleys that can be clicked into position

- Smooth-running KBK trolleys as system components

- Low-headroom travelling hoists for optimum utilisation of the available height

- Double chain hoist for mechanically synchronised lifting, e.g. for long material or large-volume components

Your Contact

Demag Cranes & Components Corp.

6675 Parkland Blvd., Suite 200

Cleveland, Ohio 44139

United States

Product information

The benefits at a glance

Click-fit trolleys

- Simple click-fit installation

- Articulated trolleys (minimum curve radius: 31.5 in (800 mm))

- Easily adaptable to standard-profile or parallel-flange sections

- High safety and reliability thanks to integrated drop-stop and lift-off protection

- Universal solutions for loads up to 1,200 lbs (550 kg)

- Flange widths from 1.06 to 3.58 in (50 to 91 mm)

U/RU push-travel trolleys

- Excellent travel characteristics

- Fast and simple installation

- Can be used on parallel and sloping flanges

- Smooth travel, low travel resistance

- Negotiate curves down to a minimum radius of 39.4 in (1,000 mm)

- Drop stop integrated into the side cheek

- Extremely low girder wear

- Designs with polyamide or steel rollers

- Compact, state-of-the-art industrial design

- Four sizes: U 11 up to 2,400 lbs (1,100 kg),

- U 22 up to 4,800 lbs (2,200 kg),

- U 34 up to 7,500 lbs (3,.400 kg),

- RU 56 up to 12,000 lbs (5,600 kg)

E 11 to E 34 electric travel drives

- Smooth starting and braking

- Low-sway load handling

- Fast installation and commissioning

- Designed for operation with DC-Pro chain hoists

- Control via DSE 10-C/DSE 10-CS control pendants

- Fast availability thanks to plug-&-drive: plug-in connection to DC-Pro chain hoists

- Simple installation of the control pendant for long/cross travel

- Optional: cross-type limit switches for fast-to-slow and final limit-switch cut-off

KBK trolleys

- E 22 fitted as standard with RF 125 friction-wheel travel drive for use with KBK modular crane system

- Short approach dimensions for vertical mounting arrangement

Low-headroom hoist

- Load capacity up to 4,400 lbs (2,000 kg)

- Optimized design for maximum utilization of the available height

- Can be used for all trolley types

Double chain hoist

- Load capacity up to 5,500 lbs (2,500 kg)

- Hook center distances from 21.5 in to 126 in (550 mm to 3,200 mm)

- Possible designs: stationary, traveling, for operation with KBK and for articulated trolleys

- Reduced polygon effect and longer chain hoist service life since no additional chain return sprockets are needed

- Suitable for higher speeds

- Asymmetric load distribution permitted

Technical data

Selection table

|

Max. dis- placeable weight incl. |

Travel drive |

Travel speed at 50/60 Hz | Possible trolleys |

Max. Weight lbs [kg] |

|||

| Steps | Stepless | ||||||

| Vrated at full load ft/min [m/min] |

Vmax at partial load1) [m/min] |

V at full load ft/min |

V at partial load ft/min[m/min] |

||||

| 2,420[1,100] | E 11 | 80/20[24/6] | 30/7.5 |

4-80 [1.2-24] |

5-100[1.5-30] | U 11 | 8.8 [4] |

| 4,840[2,200] | E 22 | 80/20[24/6] | 30/7.5 | 4-80 [1.2-24] | 5-100[1.5-30] | U 22 U 34 |

11.2 [5] |

| 4,840[2,200] | E 22 | 88/22[27/7] | 33/8 | 4.6-88 [1.4-27] | 5.4-108[1.65-33] | RF 125 | 11.2 [5] |

| 7,480[3,400] | E 34 | 46/11.5[14/3.5] | - | 2.3-46 [0.7-14] | - | U 34 | 11.2 [5] |

| 12,320[5,600] | EU 56 |

48/16*[12/4] 96/24* [24/6 ] 160/40*[40/10] |

- | On application | RU 56 | 19.4[8.8] |

1) Possible by programming other parameters

2) Max. displaceable weight/max. gradient 1% > 1% on request;*: at 60 Hz

Curve radii for trolleys

| Trolleys | Load capacity |

Runway girder | Travel wheel material | |||

| Push travel | Electric travel | |||||

| lbs [kg] | Flange width in.[mm] |

Rmin [in] |

Flange width in [mm] | Rmin [mm] in. | ||

| CF 5 | 1,210[550] | 1.97 - 3.58 [50-91] | [31.5]800 | - | - | Plastic |

| U 11 DC EU 11 DC |

2,420[1,100] | 2.28 - 12.2 [58-310] | [39.4]1,000 | 2.28 -12.2 [58-310] | 78.8[2,000] | Plastic 2) |

| U 22 DC EU 22 DC |

4,840[2,200] | 3.23 - 7.87 [82-2004) ] | [78.8]2,000 | 3.23 - 7.87 [82-2004)] | 118.2 [3,000] | Spheroidal-graphite cast iron 3) |

| U 34 DC EU 34 DC |

4,840 7,480[2,200 |

7.91 -12.2 3.23 - 12.2 [201-3101) 82-3101) ] |

[78.8]2,000 | 3.23 - 12.2 [82-3101)] | 118.2[3,000] | Spheroidal-graphite cast iron |

| RU 56 DC EU 56 DC |

12,320[5,600] | 3.85 - 12.2[98-310] | [78.8]2,0005) | 3.85 - 12.2 [98-310] | 98.4 [2,5005)] | Spheroidal-graphite cast iron |

1) Flange width for DC 16/25 = 90-310 mm (3.54 -12.2 in.)

2) Steel travel wheels optional

3) Plastic travel wheels on request

4) Flange width for DC 16/25 = 90-200 mm (3.54 - 7.87 in.)

5) From flange width 106 mm (4.17 in.)

The specified curve radii apply for normal applications. Contact the manufacturer or his representative for frequent curve travel operation (e.g. automatic installations).