Simply reliable – to meet your everyday needs

Simply reliable – to meet your everyday needs

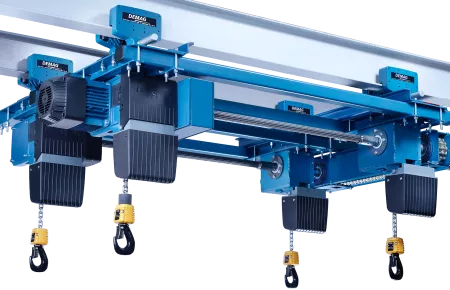

DC-Com chain hoist

DC-Com chain hoist

High quality for everyday needs

Our DC-Com chain hoist is the right solution for your everyday needs. Designed for applications with typical requirements, DC-Com chain hoists are proven, simple and highly reliable. DC-Com units can be integrated into the rails of our KBK modular crane system or installed on I-beam girders, where our U 11–U 22 generation of trolleys provide smooth load transport.

- Simple commissioning

- Ergonomic handling

- Service-friendly

- FEM classification 1Am and 2m

- 24 V contactor control

- Two hoist speeds as standard

- Demag DC Chain Hoists are Hoist Manufacturer Institute certified. This means we are one of the industry’s leading suppliers of hoist equipment.

Your Contact

Demag Cranes & Components Corp.

Demag Cranes & Components Corp.

6675 Parkland Blvd., Suite 200

Cleveland, Ohio 44139

United States

Product information

The benefits at a glance

Reliable performance

- Various sizes with load capacities up to 4,400 lbs (2,000 kg)

- Standard 16 ft and 26 ft (5m and 8m) hook path

- Elapsed operating time counter and diagnosis interface

Excellent availability and ease of operation

- Available direct

- Fast and simple commissioning due to plug connections

- Ergonomic handling

- Service-friendly

High safety and reliability

- High-quality powder-coated surfaces for improved protection and a longer service life

- 24 V contactor control

- Slipping clutch with automatic cut-out by means of speed monitoring

- IP 55 enclosure for chain hoist and trolley

Great versatility

- Two hoist speeds

- Interface for electric travel

- Optional operating limit switches up to 2,200 lbs (1,000 kg)

U 11–U 34 trolleys

- Push travel in three sizes

- Fast and simple installation

- Can be used on parallel and sloping flanges

- Smooth travel and low travel resistance

Technical data

DC-Com selection table

| Load capacity lbs [kg] |

Chain hoist type |

Reeving | Hoist speed |

CDF [%] |

Hook path ft [m] |

Group of mechanisms FEM/ISO |

|

| ft/min[m/min] at 50 Hz |

ft/min[m/min] at 60 Hz |

||||||

| 175 [80] | DC-Com 1 | 1/1 | 26.2/6.6[8.0/2.0] | 32/8[9.6/2.4] | 40/20 | 13.1,16.4 and 26.2 [4, 5 and 8] | 3m/M6 |

| 220/275[100/125] | 2m/M5 | ||||||

| 350 [160] | DC-Com 2 | 20/5[6.0/1.5] | 24/6[7.2/1.8] | 25/15 | 2m/M5 | ||

| 440/550[200/250] | 1Am/M4 | ||||||

| 690 [315] | DC-Com 5 | 14.8/3.7[4.5/1.1] | 18/4.5[5.4/1.3] | 2m/M5 | |||

| 880/1100[400/500] | 1Am/M4 | ||||||

| 1,380 [630] | DC-Com 10 | 131/3.3[4.0/1.0] | 16/4[4.8/1.2] | 2m/M5 | |||

| 1,750/2,200[800/1,000] | 1Am/M4 | ||||||

| 2,750 [1,250] | 2/1 | 2m/M5 | |||||

| 3,500/4,400[1,600/2,000] | 1Am/M4 | ||||||

*) Longer hook paths on request

Application examples

Application examples

KBK double-girder suspension crane with DC-Com chain hoist in a maintenance workshop for aircraft equipment

Safe and reliable handling also at greater lifting heights: DC-Com chain hoist installed on a KBK single-girder suspension crane

Maximum lifting height with a DC-Com chain hoist installed on a raised crab operating on a KBK double-girder suspension crane

Tried and tested combination: DC-Com on a KBK wall-mounted jib crane