Safe, reliable and simple to control

Safe, reliable and simple to control

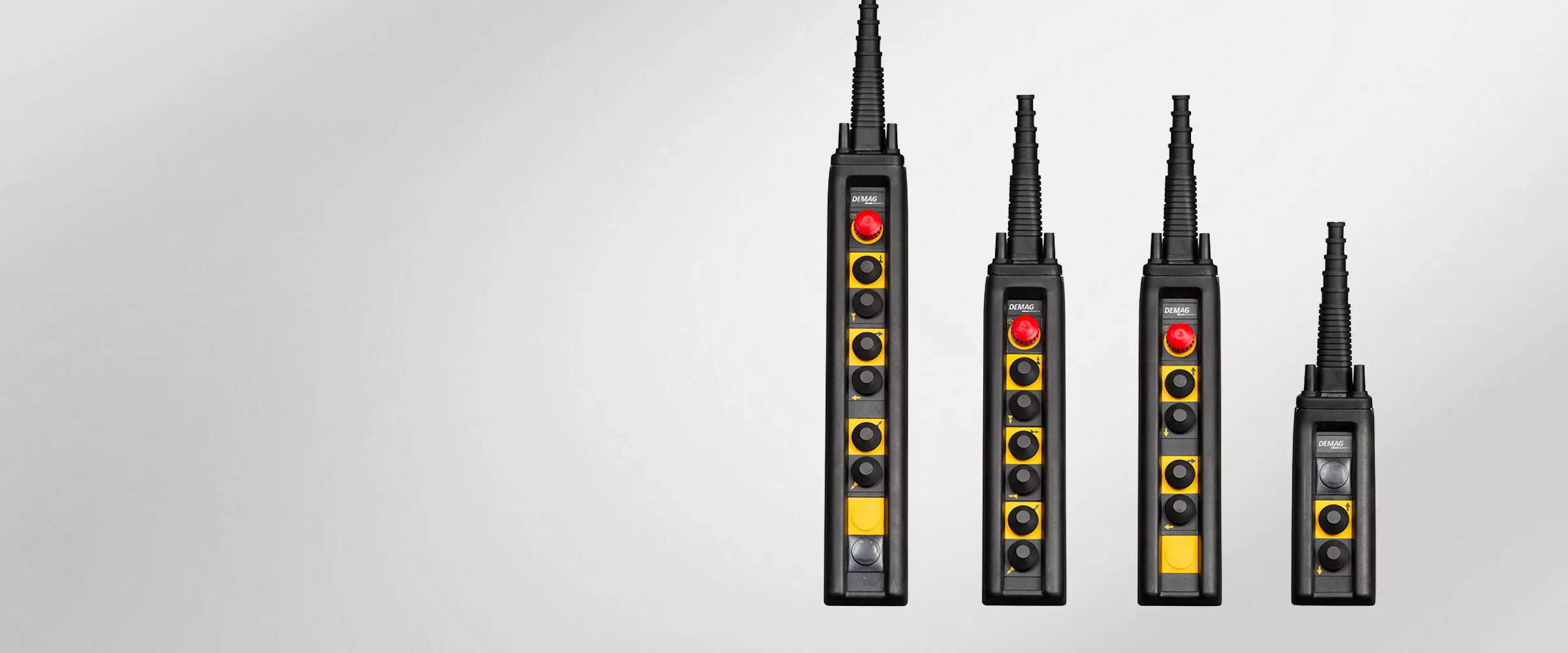

DST control pendants

DST control pendants

Safely control simply everything

DST control pendants are engineered for universal operation of cranes, hoists and machinery.

- Three sizes with multiple combinations of operating and switching elements

- Ergonomic design and operation

- Switching elements for direct and contactor control

- High switching capacity

- High operating reliability

Your Contact

Demag Cranes & Components Corp.

Demag Cranes & Components Corp.

6675 Parkland Blvd., Suite 200

Cleveland, Ohio 44139

United States

Further information

The benefits at a glance

Individual configuration

- User-friendly design in various configurations with 3, 6, 7 or 9 operating elements

- Individual configuration and combination of two DST pendants for up to 18 openings

Convenient operation

- Easy to operate due to ergonomic housing design

- Sloping control pendant design permits operators to work in a natural, comfortable posture

High safety and reliability

- High operating reliability thanks to additional strain relief elements

Technical data

DST series control pendants offer the following outstanding technical details:

- Permissible ambient temperatures for rubber and thermoplastic parts -13°F to +158°F, housing -40°F to +302°F

Safety

- Switching distances and forces to DIN 33401, holding force < 1.8 lb (8 N)

- Positive opening of interlocking contacts in the switching elements

- Movements in opposite directions cannot be simultaneously actuated

- Protective insulation to VDE 0100 Part 410

- IP 65 enclosure to DIN VDE 0470/EN 60529/IEC 529

Control

- 3, 7 or 9 openings in a single row (including special inserts)

- Two DST 6, 7 or 9 pendants can be combined for up to 18 openings (in two rows)

- Switching elements for single-stage, two-stage or variable control

- Simultaneous 2-pole switching for direct control

Housing

- Enclosure made of fiberglass-reinforced polyester with high resistance to impacts

- Flame-resistant and self-extinguishing

- Highly resistant to spirits, ether, petrol, turpentine, benzene, grease, oil, dilute acids or alkaline solutions.

| Main current switching elements | ||||||

| Type | SES 1 Z | SES 2 Z | SEDN | |||

|---|---|---|---|---|---|---|

| Type | Single-stage switching element 2 NC + 2 NO |

Two-stage switching element 2 NC + 2 NO in the 1st stage 2 changeover contacts in the 2nd stage |

Single-stage crane switch (emergency stop), 3 NC |

|||

| Utilisation category to VDE 0660/ EN 60947 |

AC 3 / AC 4 | AC 3 / AC 4 | AC 1 | |||

| Control current switching elements | ||||||

| Type | SES 1 | SES 2 | SESN | |||

| Type | Single-stage switching element 1 NC + 1 NO |

Two-stage switching element 1 NC + 1 NO in the 1st stage 1 NO in the 2nd stage |

Single-stage switching element (emergency stop), 1 NC + 1 NO |

|||

| Utilisation category to VDE 0660/ EN 60947 |

AC 15 | AC 15 | ||||

| (Main current) and control current switching elements | ||||||

| Rated operating voltage [V] | 230 | 400 | 500 | 230 | 400 | 500 |

| Rated operating current [A] | 10 (20) |

6 (12) |

4.5 (9) |

Ith 2 | 25 | (for breaking capacity up to 5.5 kW) |

| Nominal insulation voltage | Ui 500 V~ to VDE 0110, CSA 150Vac |