Simultaneous control of several drives

Simultaneous control of several drives

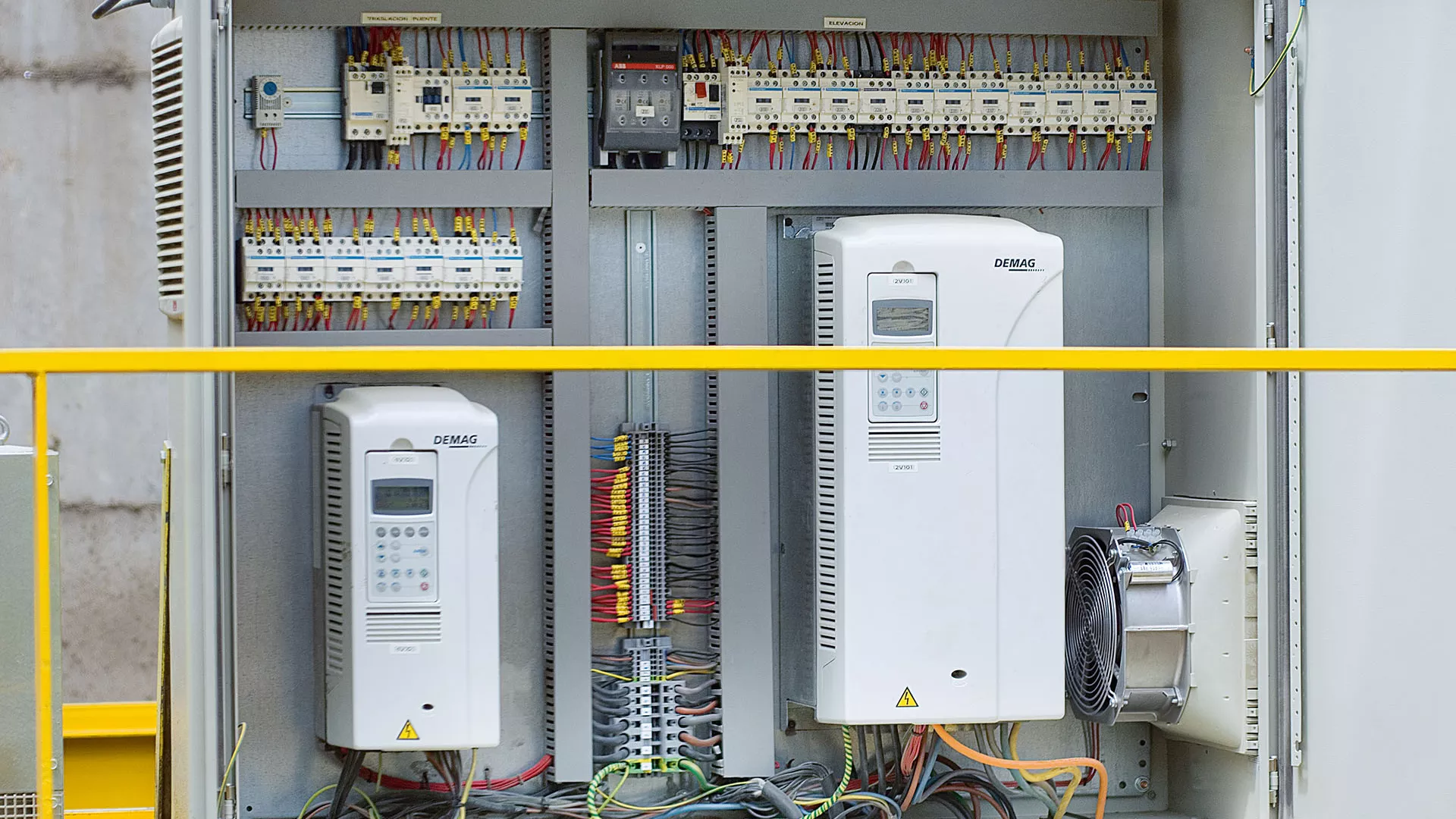

Dedrive Pro

Dedrive Pro

Strong performance up to 560 kW

Our Dedrive Pro frequency inverters are high-performance components ranging from 1.5 to 560 kW for 380 to 690 V systems. They are the solution to satisfy a variety of requirements and have firmly established their position in the industry. We have developed sophisticated crane functions to meet special requirements in your company.

- Infinitely variable motions for travel, lifting, turning and slewing applications

- Range of outputs in seven sizes

- Additional applications with supplementary options

- Also available as complete application modules

Your Contact

Sachin Pange

Sachin Pange

Aker Solutions Building. Level 3, Survey no. 75/2/3, Baner, Pune, 411045 Pune, Maharashtra, India

Phone:

9673330297

Email:

Product information

The benefits at a glance

- Simultaneous control of several drives

- Ideal acceleration and braking characteristics

- High level of safety: STO (Safe Torque Off) available as an option for all sizes

- Rated output may be temporarily exceeded, if required

- Special crane functions

- Line reactor and line filter (optional) always integrated

- Simple installation and maintenance

Extension options

- IP 55 for operation in arduous environments (up to size R6)

- Two different applications can be served by switching over parameter sets

- Fibre optic technology for fast system communications with several inverters

- Integrated speed and torque monitoring

Technical data

Hardware

- Motor outputs from 1.5 to 560 kW

- Rated voltage: 380 – 415 V, 380 – 500 V, 525 – 690 V (+/-10%)

- 1.5 times overload capability for 60 seconds

- Short-circuit/earth-fault resistant motor circuit output

- CE, CSA and UL listed

- IP 55 enclosure up to size R6 (optional)

- Master/slave capable (fibre optic, optional)

- Integrated line filter (optional)

- Integrated line reactor

- Integrated brake chopper

- Evaluation of motor temperature detector

Optional functions

- Communications modules for field bus network

- Extension modules to add control inputs and outputs as well as speed encoder evaluation

- External PTC thermistor evaluation

- Keypad terminal for parameter programming and commissioning

- Motor potentiometer via keypad terminal

- DriveWindow PC software for convenient parameter programming and diagnosis as well as visualisation

Software

- Control of cylindrical and conical-rotor motors

- Automatic parameter identification

- Direct torque control with/without encoder for fast compensation when loads change

- Speed and torque monitoring

- Special function for smooth acceleration

- Two switchable data sets (e.g. control, ramp or motor switchover)

- Setpoint memory, setpoint steps (4-stage) and analogue bipolar/unipolar control modes

- Programmable joystick characteristics

- Load-dependent speed for hoist operation with field weakening (“optimised performance”)

- Load spectrum calculation (also depending on the speed)

- Speed or torque control freely selectable

- Master/slave function, electronic gearbox and closed-loop control

- Intelligent braking logic system for brake monitoring by evaluation of the corresponding feedback contacts

- Comprehensive diagnosis functions